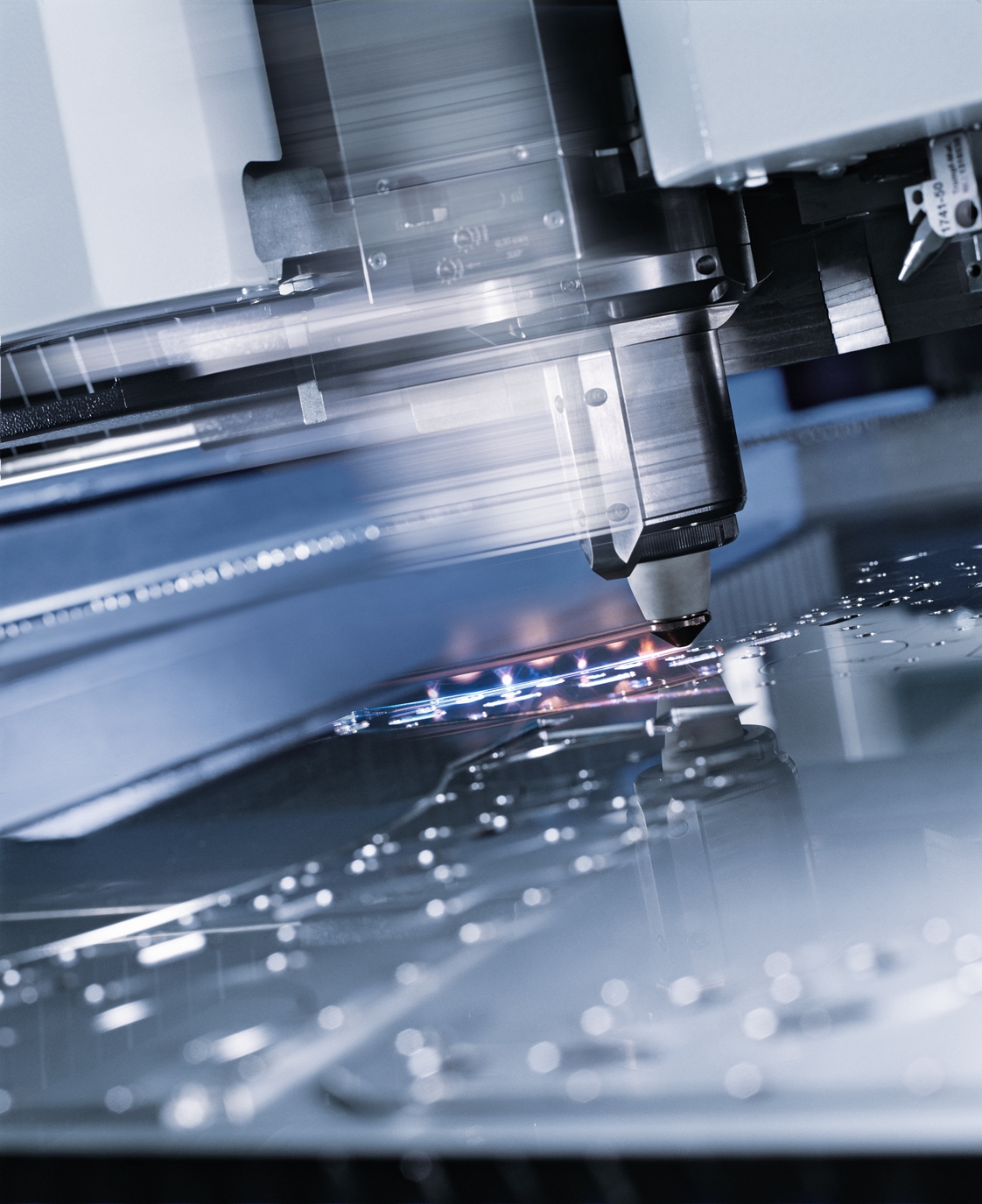

Flat Bed Laser Cutting

Laser Profiles operate the latest fibre machines, providing highly efficient and cost-effective laser cutting for plates up to 40mm in all standard material grades, including mild steel, stainless steel, and aluminum.

Competitive Prices

Affordable and precise laser-cut profiles at competitive rates.

Fast Turnaround

Quick and reliable laser cutting with fast turnaround times.

Nationwide Delivery

UK Delivery: Reliable laser-cut profiles shipped nationwide.

Laser Profiling

Laser Cutting Mild Steel

Max thickness: 30mm

Laser Cutting Stainless Steel

Max thickness: 30mm

Laser Cutting Aluminium

Max thickness: 30mm

Laser Cutting Copper

Max thickness: 16mm

Laser Cutting Brass

Max thickness: 12.7mm

Laser Cutting Services

Advantages of Laser Cutting

Explore the myriad benefits of laser cutting, offering precision, versatility, speed, and efficiency, ideal for intricate designs and rapid production.

Precision

Laser cutting guarantees precise, intricate designs with minimal material waste due to its high accuracy and tight tolerances.

Versatility

Laser Cutting can cut an array of materials including metals, plastics, wood, leather, and fabric, catering to diverse industries and applications.

Speed

Laser cutting surpasses traditional methods in speed, swiftly slicing through materials to boost productivity and shorten lead times.

Clean Cuts

Laser cutting yields clean, burr-free edges, diminishing the necessity for additional finishing procedures.

Automation

Effortlessly integrated into automated processes, laser cutting boosts efficiency, cutting costs, and enhancing production.

Non-contact

Laser beams, without direct contact with materials, minimise wear, maintenance, and extend machinery lifespan.

Complexity

It enables the crafting of intricate patterns and complex geometries, perfect for precise cuts and challenging designs.

Customisation

Laser cutting simplifies customisation and prototyping, ideal for unique designs or small-batch production.

Eco-Friendly

With minimal waste, low energy usage, and reduced emissions, laser cutting is environmentally friendly.

Cost-Effective

The long-term savings from increased efficiency, waste reduction & reduced labor costs make laser cutting economically feasible.

Our Laser Cutting Capabilities

We are part of the WEC Group, the UK’s largest laser cutting company, renowned for its advanced capabilities in precision cutting, welding, and fabrication. Our state-of-the-art facilities and experienced team enable us to handle a wide range of materials and complex projects, ensuring the highest quality and efficiency for our clients.

Working Range (Y Axis)

Y: 2000mm

Working Range (X Axis)

X: 4000mm

Max Thickness

30mm

Laser Profiles use ISO 9001:2015 to drive production, ensure full traceability and satisfy customer needs

Laser Profiles is dedicated to providing outstanding engineering and fabrication services. Quality is at the heart of our operations, evidenced by our accreditation to the latest industry standards and our in-house QA team that rigorously inspects every part. Our primary objective is to surpass the needs and expectations of our customers.

Leveraging extensive experience, we cater to a diverse range of industries, including aerospace, defense, nuclear, marine, and oil & gas.

Frequently Asked Questions

Flat bed laser cutting refers to a method where materials are placed on a flat, stationary surface (bed) during the laser cutting process. A laser beam is then directed onto the material from above, cutting through it according to a programmed design or pattern. This method is commonly used for cutting sheets of materials like metal, plastic, wood, and fabric, offering precise and versatile cutting capabilities for various industrial and manufacturing applications.

Metal laser cutting is highly valued for its precision, versatility, and efficiency across various applications. It offers precise cuts with minimal tolerance, suitable for intricate designs and diverse metals such as steel, aluminium, and copper. The process is faster than traditional methods, delivering clean edges without burrs or rough surfaces, thereby reducing the need for additional finishing. Laser cutting can be automated through CNC programming, enabling fast production and customisation while minimising material waste and labour costs. Its non-contact approach and lower energy consumption also make it a cost-effective and environmentally friendly cutting solution in manufacturing and fabrication industries.

- Stainless Steel

- Mild Steel

- Aluminium

- Brass

- Copper

- Bronze