Affordable and precise laser-cut profiles at competitive rates.

Quick and reliable laser cutting with fast turnaround times.

UK Delivery: Reliable laser-cut profiles shipped nationwide.

It is a material processing technique that uses a highly focused beam of light to cut, engrave, or etch materials with precision. The laser melts, burns, or vaporises the target material.

This type of laser-based manufacturing can produce components ranging from small intricate parts to large structural elements. It is compatible with a wide range of materials, including mild steel, stainless steel, aluminium, copper, brass and more.

Its precision, speed, and flexibility have made laser cutting a preferred method for both prototyping and high-volume production.

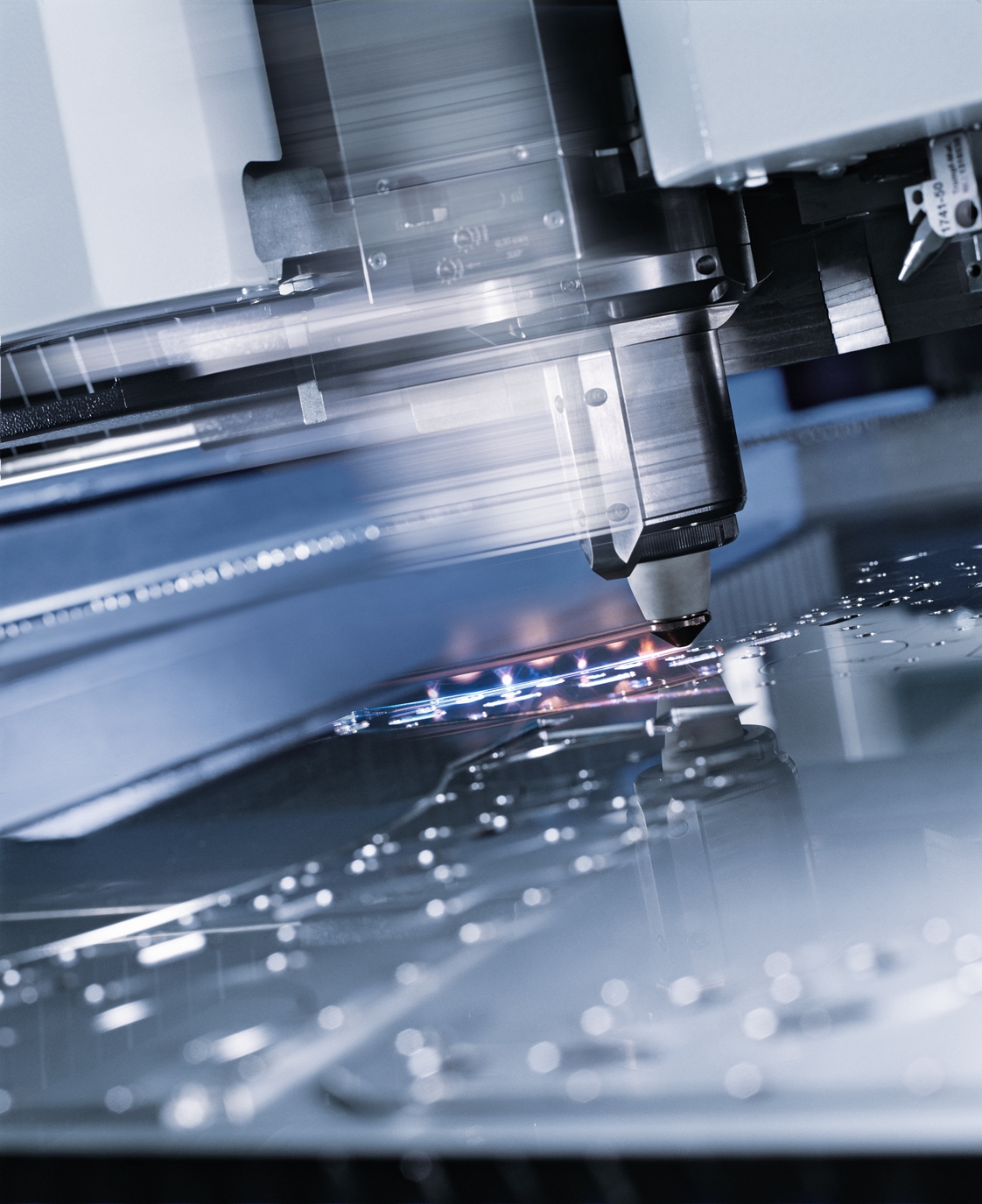

Flatbed Fibre Laser

Fibre laser flatbed cutting offers exceptional precision, speed, and efficiency when processing sheet metal. Using a high-powered laser beam, the machine can produce clean, accurate cuts with minimal heat distortion and excellent edge quality. Suitable for a wide range of materials including mild steel, stainless steel, and aluminium, flatbed laser systems are ideal for producing intricate profiles, prototypes, and high-volume production runs.

Tube Laser Fibre

Fibre laser tube cutting provides an advanced solution for processing round, square, rectangular, and complex tubular profiles with outstanding accuracy. The technology allows for fast, automated cutting of holes, slots, bevels, and detailed features directly into tube or pipe, eliminating the need for secondary machining.

A typical laser profiling process consists of the following stages:

Design and Programming

The first step involves creating a digital design using CAD software. The file is then converted into a format suitable for the laser cutter, defining cut paths, speed, power, and gas flow settings.

Material Preparation

The material is positioned on the cutting bed. It must be flat and clean to ensure consistent quality and precision. Reflective surfaces may require protective coatings to prevent damage or reduced cutting efficiency.

Laser Cutting

The laser is focused on the material, and energy is delivered to the surface to cut or engrave the desired shape.

Finishing

After cutting, parts may require minimal finishing, such as polishing, depending on the material and application.

Inspection and Quality Control

Finished parts are inspected for dimensional accuracy, edge quality, and surface integrity. Consistent quality is crucial in high-precision industries such as aerospace.

Laser machining offers exceptional precision, achieving tolerances as low as ±0.1 mm, which makes it ideal for intricate designs and complex designs. Its narrow width and accurate cutting help minimise material waste, saving cost and improving sustainability. The process is highly versatile, capable of working with metals such as stainless steel, making it suitable for a wide range of industries and applications.

Laser processing is also fast and efficient, particularly when automated, providing high repeatability and suitability for both low and high-volume production. As a non-contact process, it avoids tool wear, unlike mechanical cutting methods, which reduces maintenance costs and extends equipment life.

Material Restrictions

Certain materials, such as highly reflective metals or extremely thick components, may be challenging to cut effectively.

Safety Requirements

Operators must adhere to strict safety protocols due to intense light, fumes, and potential fire hazards.

Heat-Affected Zones

Laser profiling services generate heat, which can cause warping or microstructural changes in sensitive materials if not carefully managed.

Skilled Operators Required

While automation is common, programming, setup, and troubleshooting still require skilled personnel to ensure optimal performance.

Interested in other cutting services that don’t have these restrictions? Click here to visit our Waterjet and plasma cutting website.

Laser cutting is a modern manufacturing process that blends precision, speed, and versatility. Its ability to handle a wide variety of materials, coupled with minimal waste and exceptional accuracy, has made it a staple in industries ranging from automotive and aerospace to signage and medical devices. Ongoing innovations, including higher-power fibre lasers and integrated automation, continue to expand the applications and efficiency of laser cutting.

For businesses looking to create customised components, intricate designs, or high-quality metal profiles, we offer a reliable solution that delivers both accuracy and repeatability. Contact us below to discuss your requirements or request a quote.